Hermès Reveals Their Design Secrets & Demonstrates Their Craft at Festival des Métier

Every wonder why an Hermès scarf costs $2,000? Or, what makes an Hermès so special?

Luxury brand, Hermès swooped in with Festival des Métier at the Design Exchange this week giving us an insider’s view of the namesakes top secrets in crafting their most coveted pieces. Rarely does the audience understand the immense amount of work, thoughtfulness and process that the fashion house sets in place to maintain the heritage and value that the artisans bring us. At Festival des Métier, Hermès lays it all on the line, celebrating its artful marriage of luxury, art and fashion, rarely ever speaking of the lengthy production and review process involved in maintaining the integrity, heritage, craftsmanship and quality of the brand.

At the first station, a Maroquinier (Leather Artisan) is seen hand-stitching a Kelly handbag together. “They first test the person’s sewing ability before accepting them into the school.” It’s no surprise that the atelier brings on the best of the best, with skillful handwork perfecting every stitch on every bag. When asked about the time involved to take a bag from start to finish she sighs thoughtfully, “It depends on the type of leather and the amount of work involved. I don’t know how long it takes, but it’s very long.”

Caressing the buttery leather through his fingers, the leather craftsman swiftly cuts through the fabric to fashion the pieces required to create a set of impeccably finished gloves.

It takes 3.5 hours to do the sewing, but can take up to 20 days to finish a pair.

I reach out and touch an incredibly luxurious piece of leather with wool lining. “We develop a fall and spring collection, often working with deer leather and cashmere or wool lining.” When discussing the quality control and detailed work involved, we discover it could take as much as 20 steps or operations. If the leather is thin, the gloves might enter a special sewing machine, but most of the time, they’re hand-sewn, finished and enter through an extensive quality control process.

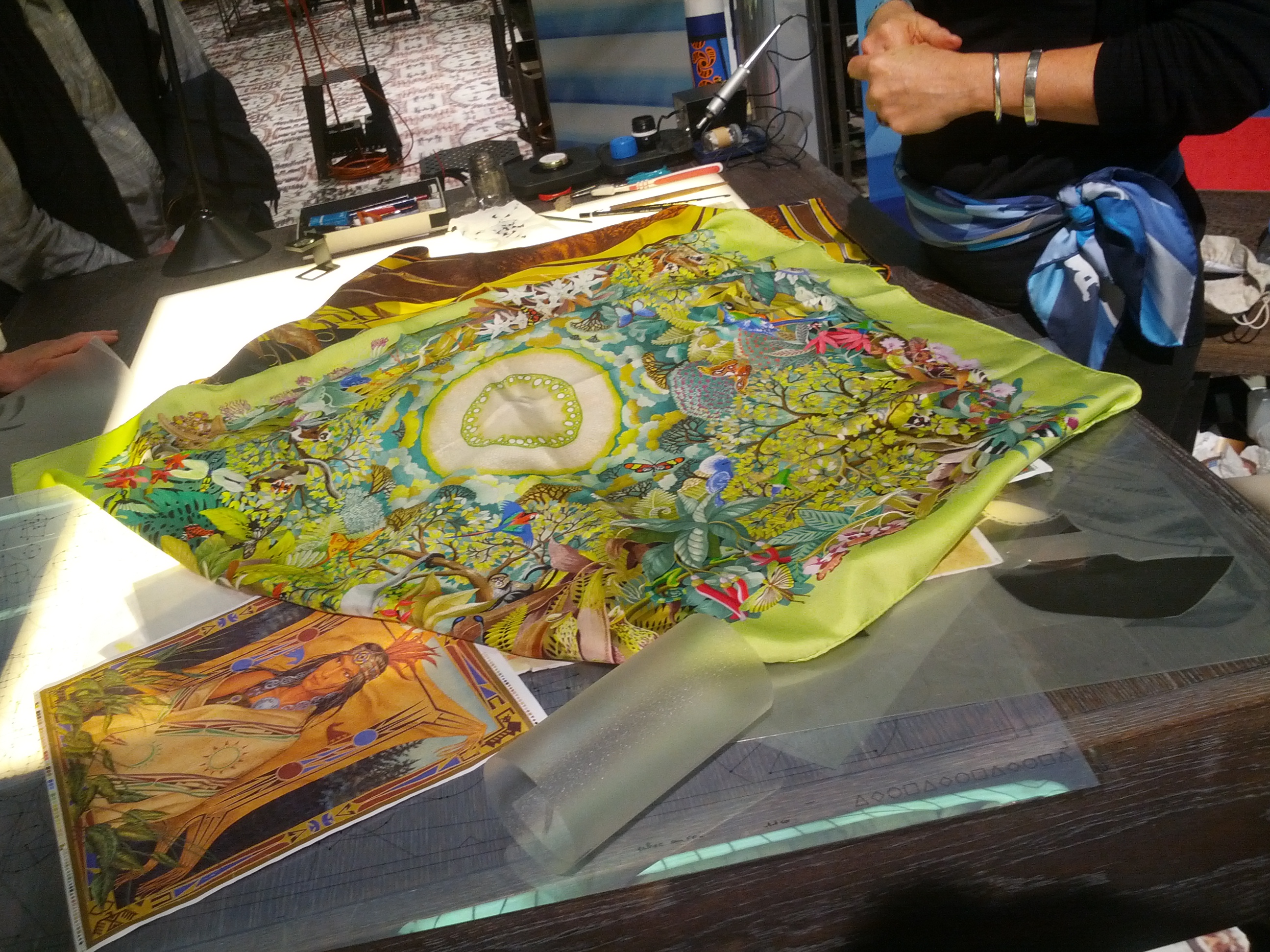

It’s not hard to fall in love the most luxurious silk scarves on the market. The amount of work involved in making a scarf is an incredibly lengthy one, taking 2 years to bring a scarf from start to finish.

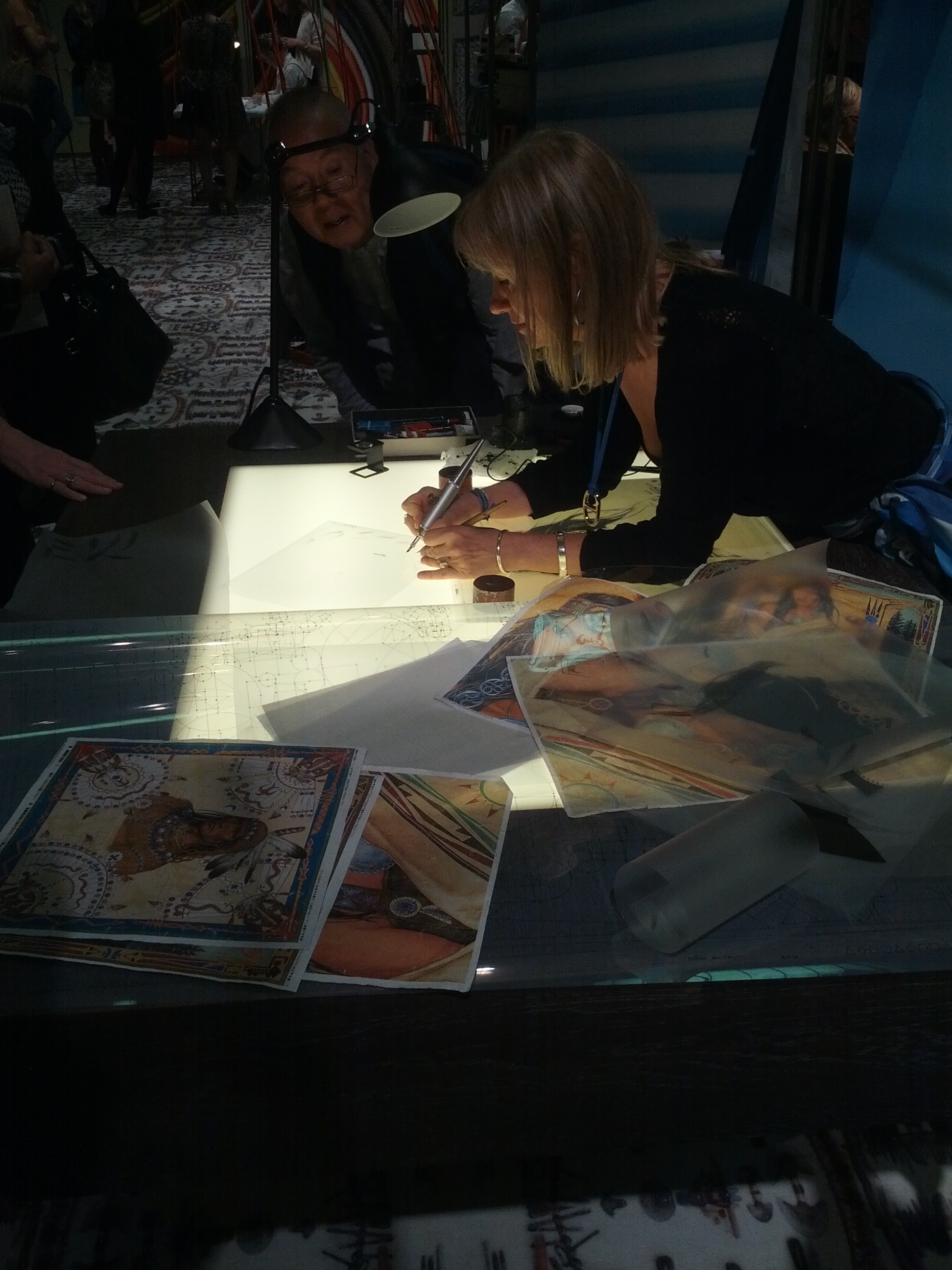

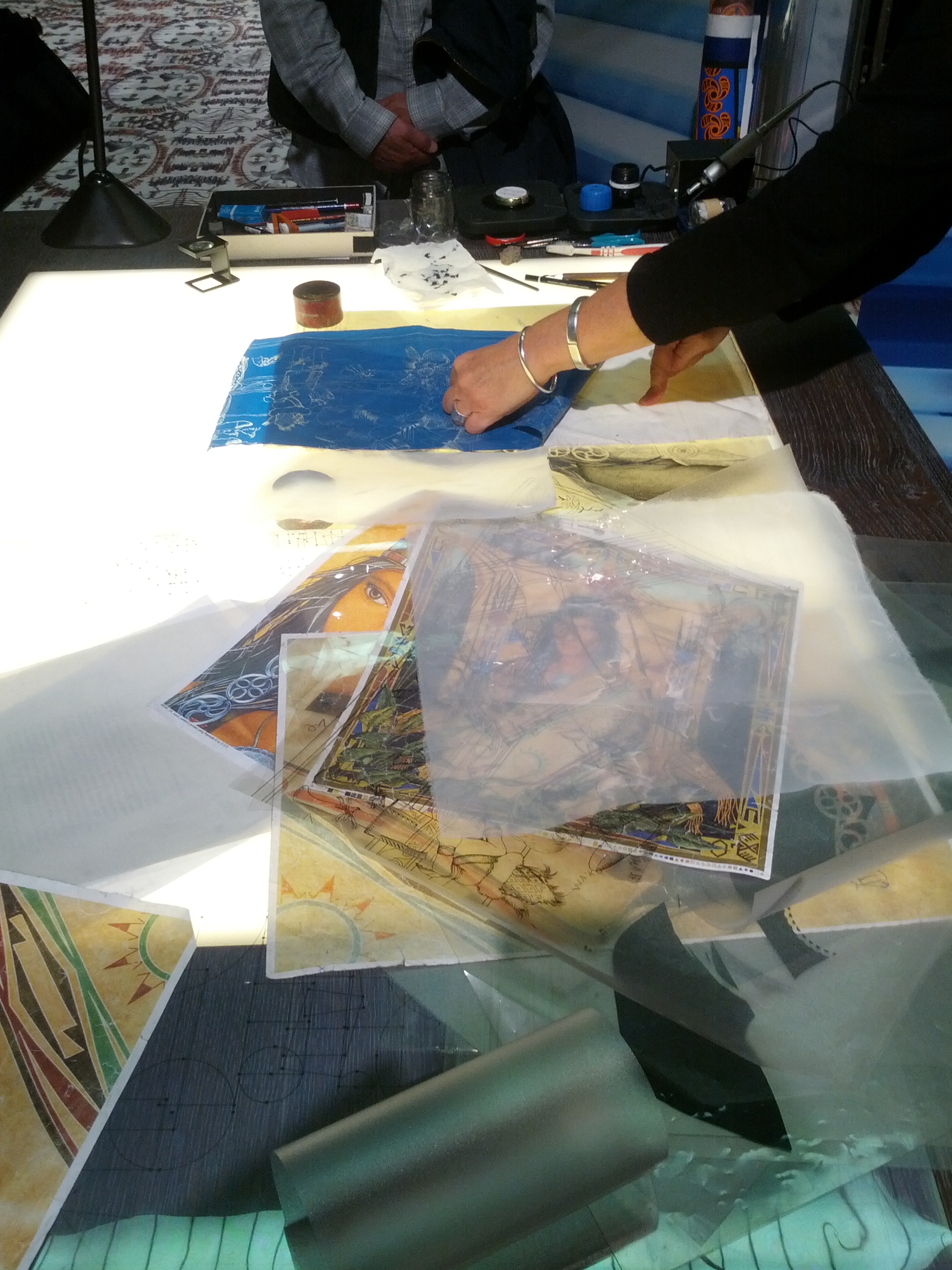

First, the Dessinateur (Engraver), who works solely on the illustration of a scarf. The Dessinateur creates one sheet for every layer of colour that is required for the screen-printing process. To keep them from tearing, the granulated paper is treated and thickened to withstand the etching and work involved in the entire process. The Dessinateur can then use pencil, brush or an electric pen to sketch out small details of each sheet required to complete the entire illustration.

The Dessinateur spends an average of 700 – 800 hours to complete one illustration, and more shockingly, a record of 2000 hours have been spent on a single design.

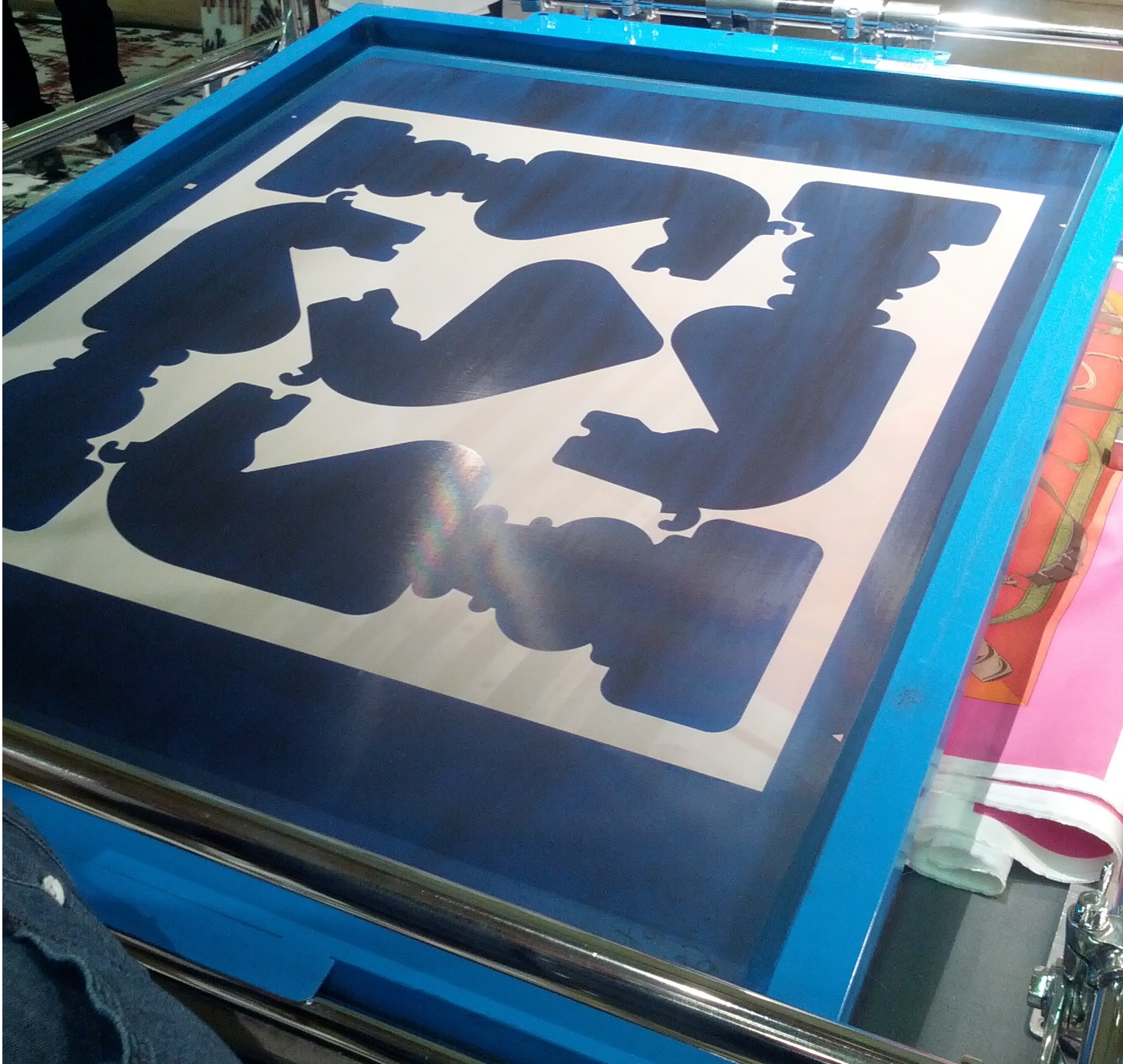

Screen Printing

Afterwards, the illustrations are screen-printed onto silk. The first print is the outline to prevent the colours from bleeding. They cook the sheet and steam it for one hour to seal the pattern in. On average, there are approximately 27 different shades that get screen-printed onto one scarf.

The most colours ever printed on the scarf is 47 colours.

When the design is complete, the scarves are sent to various people around the world to review for quality control.

Treatment of the Silk

The scarves come in 3 sizes, but for a 90 cm x 90 cm scarf, it takes 300 butterfly cocoons to make one silk scarf. That’s 450,000 meters of silk thread! The silk is woven, washed, treated with olive oil to bring out the soft, decadent textures you feel in stores.

The existing collection currently consists of over 1500 different design, with more than 75,000 hues used to make these scarves.